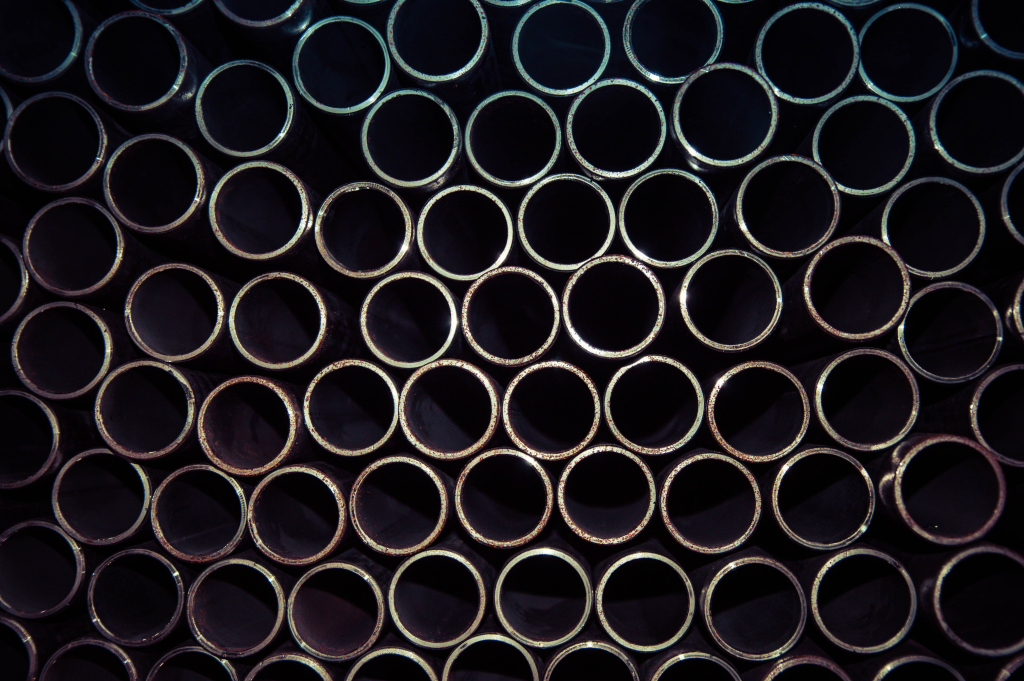

Carbon steel is frequently perceived as a less expensive alternative to stainless steel. However, with its advantages and benefits, this material deserves to be the first choice, rather than a second-rate option, in the selection of piping systems in some cases. The single most important factor in choosing Carbon Steel over Stainless Steel grade is its lower cost. Because stainless steel is not required in every application, why not take advantage of the benefits of press-fitting carbon steel? In this article, we will let you know the benefits of carbon steel API pipe to production.

First of all, carbon steel gives any material it is used high tensile strength. It can be bent and stretched into any shape while retaining its strength. Because of this property, carbon steel tubing can be made thin while still holding flowing substances under high pressure. Carbon steel can withstand shock because it is a shock-resistant and highly durable alloy. Its fire resistance makes it ideal for piping systems and other structures that must withstand fires, earthquakes, hurricanes, and tornadoes.

Handling Refrigerants and Other Chemicals

Carbon steel pipes are also very good at handling refrigerants and other chemicals. They also work well in industrial settings with extremely low pH levels or extremely high temperatures. Carbon steel piping’s durability and resistance to environmental factors ensure safety and reliability across industries. Because the pipes and fittings do not need to be replaced as frequently as other systems, this translates to more years of continuous operation.

Safe

Carbon steel pipes are safe to work with and are immune to the need for pesticides to treat some other pipes. Steel pipes also can be made to any height, width, and strength required to meet the specific requirements of your job. They are also easily modifiable on-site, making them simple to install. Because steel is a very easy metal to work with, any maintenance or modifications required after installation can be completed quickly and easily.

Rust-proof and Resistant

Steel tubes, unlike other metals that rust or corrode easily, are rust-proof and resistant to other chemical reactions that cause corrosion. This makes them less maintenance-intensive than other types of tubes and pipes, allowing them to last for many years after installation. Carbon steel pipes have a larger internal diameter than other materials, such as copper or plastic, and thus a greater carrying capacity. Carbon steel pipe systems can transport more gas or fluid than other types of pipework.

Here are a few examples of steel pipe applications in residential and industrial settings:

Utilities – Steel pipes are used to encase utility lines underground and for electric power, gas lines, and water mains. Steel pipes and tubes are an excellent choice for protecting sensitive lines due to their durability and strength.

Water – Because steel is rust and corrosion-resistant, it is an excellent choice for domestic water delivery. Its strength and durability allow it to withstand pressure, shock, and vibration for many years underground.

Construction – Steel tubing is now used by many contractors and companies in building foundations and framing systems. It is also used to make handrails, poles, fences, scaffolding, chimney pipes, exhaust pipes, and temporary structures.

In conclusion, with these benefits, carbon steel pipes are not only cost-effective up front, but also cost-effective in the long run.

There are no comments